GENERAL KNOWLEDGE

The fermentation of kimchi is handled by lactic acid bacteria

After the cabbage is sprinkled with plenty of salt on neat piles and sleeps through a night, it is properly pickled and shrunk. When water escapes to the more concentrated outside, ‘protoplasmic separation’ occurs in the cells. Wash the salted cabbage with fresh water. The mix of all the materials will be inserted in between of each layer of leaves in neatly folded shape, and place them in Kimchidog(pot), carefully pile them up.

Most microorganisms are killed during the salting process, however, the salt tolerant bacteria, lactic acid bacteria will survive and ripe the kimchi. Needless to say, the microorganisms on vegetables are the main characters of fermentation. Put the kimchi in the kimchi-dok (pot) and press it tightly with the kimchi-dol (stone) to drain the air. Lactobacillus living in kimchi are anaerobic bacteria that die when oxygen is present, so they remove all oxygen. In other words, only the lactic acid bacteria that endure salt, hate oxygen, and like low temperatures survive. For reference, if I go on a trip and can’t eat kimchi for a few days, I think about it. In that case, eating yogurt with a lot of lactobacillus will relieve your desire. This is because lactic acid in kimchi soup and yogurt are similar.

🥬 Fermentation Process

1. Preparation and Salting

- Fresh napa cabbages are sprinkled with salt and left overnight in neat piles.

- Through osmosis, water moves out of the cabbage cells into the salty environment.

- This causes protoplasmic separation (plasmolysis) — cells shrink as water escapes, leading to a crisp yet softened texture.

- After salting, the cabbage is rinsed thoroughly in fresh water to remove excess salt.

Scientific Principle:

➡️ Water moves from a low-salt (inside cell) to a high-salt (outside) area.

➡️ Cells lose water → protoplasm pulls away from cell wall → texture changes.

2. Mixing and Packing

- Seasoning mix (chili, garlic, ginger, fish sauce, etc.) is spread between each leaf layer.

- The seasoned cabbages are neatly folded and packed tightly into a Kimchi-dok (earthenware pot).

- A Kimchi-dol (stone weight) is placed on top to remove air.

Why?

➡️ Lactobacillus (lactic acid bacteria) are anaerobic — they thrive without oxygen.

➡️ Tight packing prevents oxygen exposure, discouraging spoilage bacteria.

3. Fermentation by Lactic Acid Bacteria

- During fermentation, most microorganisms are destroyed by salting.

- Salt-tolerant lactic acid bacteria survive and dominate.

- These bacteria convert vegetable sugars into organic acids (mainly lactic acid).

Result:

- Sour taste, appetizing aroma, and longer preservation.

- Low pH prevents harmful bacteria from growing — it becomes a world ruled by lactic acid bacteria.

4. Ripening and Maturation

- As kimchi ferments, the acidity increases and flavor deepens.

- Well-fermented kimchi contains:

- ≈ 99% lactic acid bacteria

- ≈ 1% other bacteria and fungi

When fermentation continues too long:

- Lactic acid bacteria die off.

- Yeasts and molds become active → decomposition begins.

- The kimchi becomes over-fermented or “Mukeunji” (묵은지).

5. Temperature Control and Kimchi Refrigerator

- Traditionally, Kimchi-dok was buried underground to keep a constant cool temperature (around –1 °C to +1 °C).

- Modern Kimchi refrigerators replicate this stable, low-temperature environment —

ensuring slow, steady fermentation and preserving lactic acid bacteria longer.

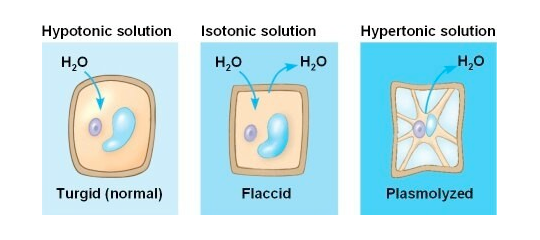

⚗️ Scientific Sidebar: Protoplasmic Separation (Plasmolysis)

| Condition | What Happens in Cells | Description |

|---|---|---|

| Low Salt (Hypotonic) | Water enters cells | Turgor pressure increases; plants stay firm and upright |

| High Salt (Hypertonic) | Water leaves cells | Cells shrink; protoplasm separates from wall (Plasmolysis) |

| Return to Water (Isotonic) | Water re-enters cells | Cell regains shape (Deplasmolysis) |

| Extreme Salt Exposure | Cells rupture | Irreversible plasmolysis; plant tissue dies |

🧩 Protoplasm separation [ Plasmolysis ]

When plant tissues are put in a high concentration solution such as sugar or salt solution, the water inside the cells goes out and the cells contract and separate from the cell wall is called protoplasmic separation. On the contrary, when the cells are in a solution with a low osmotic pressure, the external osmotic pressure is lowered, so that the flow of water is directed into the cells and cytolysis occurs through deplamolysis. Physically, through observation of protoplasmic separation and protoplasm reversion, it is possible to approximate the solute concentration in the environment around the cell as well as the velocity of a specific solute molecule across the cell membrane of the cell.

1. Osmosis, tension and protoplasm separation

In a low-concentration solution, plant cells absorb water by endosmosis, so it can be observed that the amount of water in the cells increases and the pressure increases and the protoplasm is pushed toward the cell wall. At this time the pressure that is formed into the cell wall tension called (turgor pressure), and each plant cell are obtained bearing capacity is firmly pushed to each other. This is the driving force for annual plants such as herbaceous plants to overcome the influence of gravity and to stand upright on the ground. However, since plant cells have cell walls, when they reach full turgor even with excessive osmotic inflow, more water inflow is prevented, so instead of being destroyed, they have a strong support. If the plant cell is not solid, it will not stand upright. On the other hand, when subjected to a high salt concentration environment, such as in a high salinity region, the plant cells lose water, and in this case, the vacuoles within the cells play a very important role. That is, a large amount of solute such as mannitol, sorbitol, or sugar is stored in the vacuole to prevent water from escaping from the cells, thereby maintaining the swelling pressure.

2. Mechanism of protoplasm separation

In high-concentration solutions, plant cells drain water out of the cells and lose their taut pressure. As a result, the pressure of the cell membrane pushed toward the cell wall weakens, and a gap is created between the cell wall and the cell membrane, and the plasma is peeled off from the cell wall. As a result, plant cells contract and break. When the pressure continues to decrease, it completely collapses into the cell wall. Under this condition, the plant cells atrophy and gradually the plant withers. After protoplasmic separation, in plant cells, the gap between the cell wall and the cell membrane is filled with a high concentration solution. Since water in the cytoplasm fills the space between the cytoplasm with solute, most of the water escapes, and the concentration inside the cell becomes higher and higher. Meanwhile, many plants have various mechanisms to prevent excessive moisture loss.

3. Observation of protoplasm separation of plant cells

Protoplasmic separation occurs only under extreme conditions and rarely occurs in nature. When cells are immersed in a high-concentration salt or sugar solution in a laboratory, the phenomenon of protoplasm separation can be observed, and the process of protoplasm separation can be observed under a microscope using epithelial cells of purple or pink Elodea plants or onions. . Treatment of methylene blue, a dyeing reagent, can more clearly observe protoplasm separation.

4. Types of protoplasmic separation

The phenomenon of protoplasmic separation can be largely divided into two. Concave plasmolysis is a type that occurs in a high-dynamic solution and can be reversed when the concentration of the aqueous solution in the surrounding environment decreases. During protoplasmic separation, the cytoplasm and the cell membrane contract away from the original cell wall. In other words, the cytoplasm surrounded by the cell membrane is separated from the cell wall, and cells surrounded only by the cell membrane in this state are called protoplasts. In the process of concave protoplasm separation, the protoplasts are separated from the surface of the cell wall, but the protoplasts remain connected to the protoplasms of nearby cells, creating a half-moon-shaped empty space. When the cells are put back into the storage environment, water flows into this space and ultimately regains its original shape as it enters the cells. On the other hand, convex plasmolysis is a phenomenon occurring in a low concentration solution and is an irreversible shape that causes serious damage to plants. When plant cells undergo severe protoplasmic separation, protoplasts are completely separated from the cell power and even the connection through protoplasmic liaisons is lost. In this case, even if the cells are placed in the storage liquid environment again, the tension cannot be recovered and the plant withers and dies.

When kimchi is sour, it becomes ‘mukeunji’

As the lactic acid bacteria in the pot grow slowly, this is ‘Kimchi fermentation.’ Otherwise, it is ‘decomposition’ when germs rot the material. As lactic acid bacteria propagate using nutrients in vegetables or seasonings, it releases a lot of organic acids, which causes saliva to come out and gives the distinct taste and aroma of kimchi. At this time, other microorganisms are unable to use their strength and only lactic acid bacteria hit the plate, so it is literally a world of lactic acid bacteria. Algiers free (octaves), the law is not the world that never changed. After some time in this state, the acidity (pH value) decreases (as it sours), and at some point these lactic acid bacteria become impatient and wither.

It is said that very ripe kimchi contains 99% of beneficial lactic acid bacteria and about 1% of other bacteria and fungi. However, as the kimchi becomes sour, the lactic acid bacteria die and decrease. Therefore, the mold clusters (yeasts) that have been hiding until now are gaining power, and the soup is becoming a candle. It’s a kind of decomposition. So very foxed old kimchi, mukeunji (kimchi) is a lactic acid bacteria are killed. It was said earlier that lactic acid bacteria are sensitive to temperature. So, we developed a Kimchi refrigerator, which is a ‘Korean native species’ that does not exist in the world because it has developed a product that keeps the temperature low and constant so that lactic acid bacteria do not die.

When Kimchi-dok is buried in the shade, it is the invention of Kimchi Refrigerator that realizes that the temperature in the pot is almost unchanged and maintains around 1℃ below zero. For any invention, there is nothing that is not a product of necessity and nothing that does not imitate nature!

[네이버 지식백과] 농익은 김치의 과학 – 유산균의 김치발효 (생물산책, 권오길)